The Complete Guide to Vulcanization Process of Rubber: Methods, Applications, and Benefits - [PDF Download]

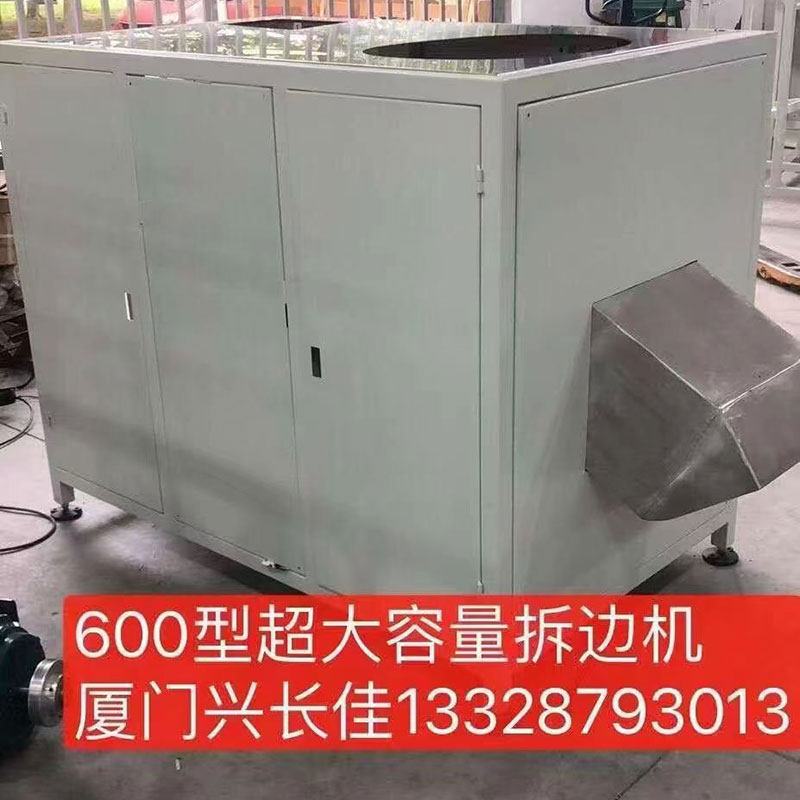

Introducing Vulcanization Process of Rubber - a revolutionary solution for enhancing the durability and quality of rubber products. This product is brought to you by Xiamen Xinchangjia Non-standard Automation Equipment Co., Ltd., a leading manufacturer, supplier, and factory based in China. The Vulcanization Process of Rubber is a highly advanced method that involves adding specific chemicals, such as sulfur, to raw rubber to improve its properties. Through this process, the rubber undergoes a chemical reaction, resulting in increased strength, elasticity, and resistance to wear and tear. Furthermore, vulcanization enhances the thermal stability and aging resistance of rubber, making it ideal for various industries. With the cutting-edge technologies employed by Xiamen Xinchangjia Non-standard Automation Equipment Co., Ltd., our Vulcanization Process of Rubber offers unmatched precision, efficiency, and reliability. Our state-of-the-art equipment ensures seamless operation, precise control over variables, and consistent product quality. Additionally, our experienced team of professionals ensures that each product meets the highest industry standards. Whether you are in the automotive, construction, or any other industry that relies on rubber components, our Vulcanization Process of Rubber is a game-changer. Trust Xiamen Xinchangjia Non-standard Automation Equipment Co., Ltd. to provide you with top-notch solutions that will enhance the performance and lifespan of your rubber products. Contact us today to discuss your requirements and experience the superior quality of our products firsthand.

Related Products